Industry 4.0 | IoT

Industry 4.0, also known as the fourth industrial revolution, refers to the use of advanced information technology in industrial manufacturing to enable connected, automated and data-driven production. The aim of Industry 4.0 is to improve the efficiency, quality and flexibility of manufacturing processes and to enable new business models.

Some technologies used in the implementation of Industrie 4.0 are:

Artificial intelligence and machine learning: These technologies make it possible to optimize and automate manufacturing processes by analyzing large volumes of data and identifying patterns.

Internet of Things (IoT): The Internet of Things (IoT) refers to the connection of machines, devices and products to each other and to the cloud to collect and analyze data. IoT technologies are important for making Industrie 4.0 systems connected and data-driven.

Cyber-physical systems: Cyber-physical systems (CPS) are systems that consist of hardware, software and networks and enable the interaction of physical and digital components. CPS are important to realize Industrie 4.0 systems, as they enable real manufacturing processes to be linked to digital models and simulations.

The experts at BITS have implemented a large number of Industrie 4.0 projects. A selection of case studies and references can be found below.

“We are happy to support you with your digital challenges and look forward to hearing from you without obligation.”

Marc Schallehn, Managing Director BITS GmbH

Gerne unterstützen wir Sie bei Ihren IT Projekten. Ich freue mich über Ihre Kontaktaufnahme.

Selection of case studies and references

Advice on IT strategy

Advice on IT strategy Flexible, innovative and sustainable - IT strategy consulting from BITS In today's rapidly evolving digital world, a solid IT strategy is essential to remain competitive in the long term. [...]

Future approaches, opportunities and risks through the use of artificial intelligence (AI) in the IT workplace

As part of the TecDays in Munich and at several on-site events, BITS addressed the opportunities and risks of AI in the IT workplace.

Seamless connection of a Shopware 6 online store with the SAP Business ByDesign ERP system

In this project, BITS successfully connected the online store of a medium-sized manufacturing company to their SAP ERP system.

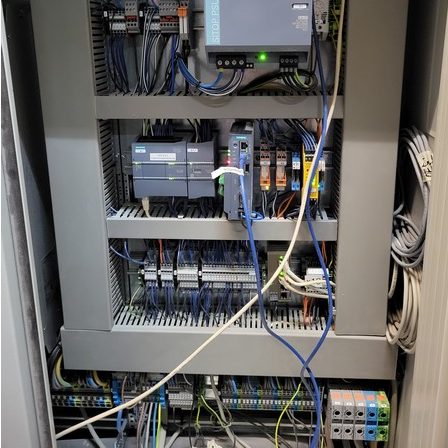

Connection of production machines of a medium-sized manufacturer to the Industry 4.0 OEE solution of BITS for monitoring and optimization of production

In this Industry 4.0 project, BITS' task was to monitor and control production machines with the help of an OEE solution in order to optimize quality, capacity utilization and costs.