Connection of production machines of a medium-sized manufacturer to the Industry 4.0 OEE solution of BITS for monitoring and optimization of production

The task in this project was to monitor and control the production machines of a manufacturer of cooling solutions in the food(easy2cool) and pharmaceutical(Licopharm) industries using an OEE (Overall Equipment Effectiveness) solution in order to optimize quality, capacity utilization and costs.

The tasks of BITS were the IT conception, the individual development of OEE functions and evaluations, as well as the individual connection of the production machines.

The Overall Equipment Effectiveness (OEE) is a key figure that describes the availability of systems in relation to production time.

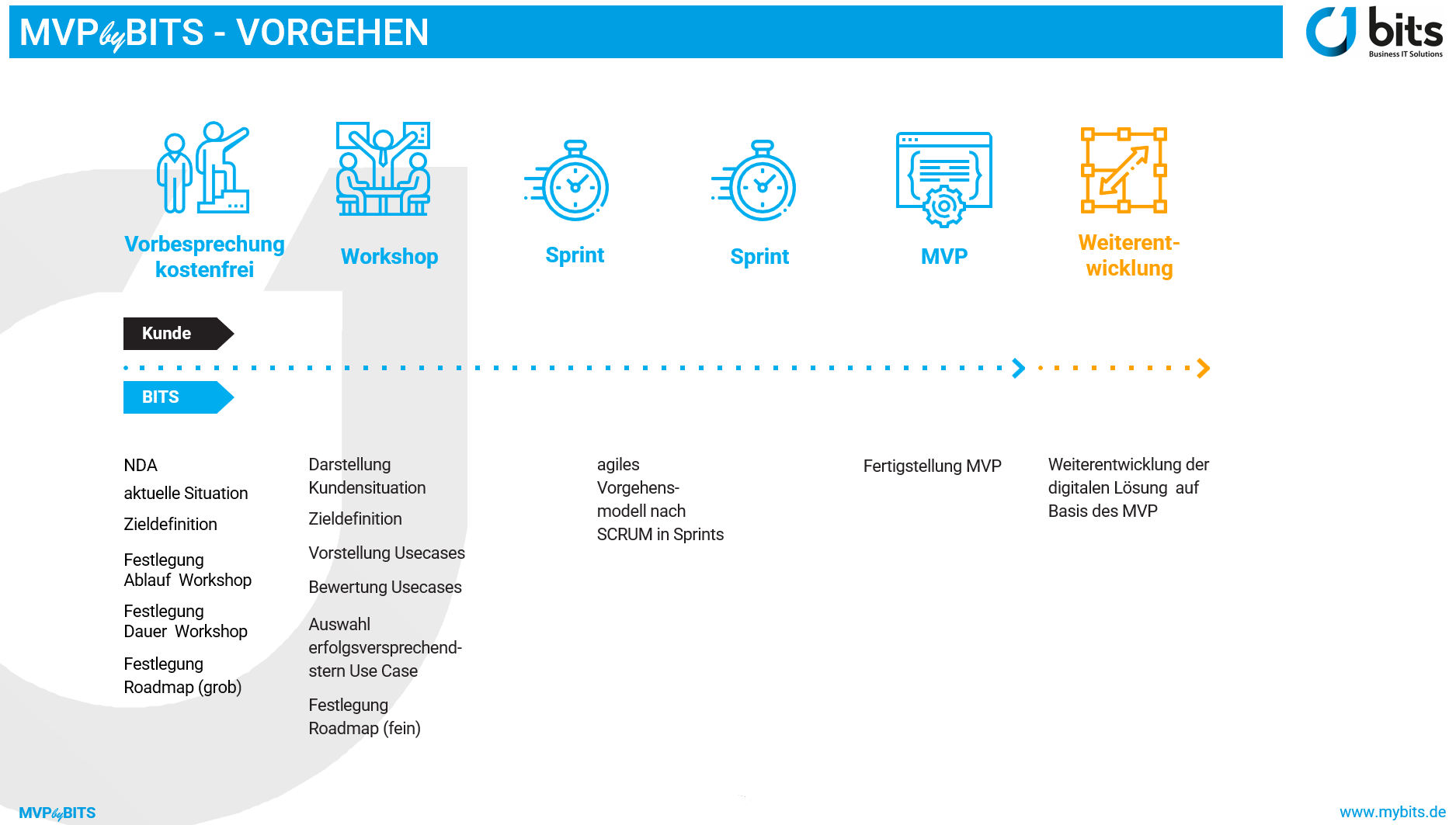

The project was carried out on the basis of the MVP procedure of BITS with the aim of being able to start with a first version as quickly as possible.

The OEE solution from BITS

“By connecting our production machines to BITS’ OEE solution, we are able to optimize our production processes in terms of quality, yield, costs and downtime. Thanks to BITS’ agile MVP process model, we were able to implement the project in a very short time, even though we had additional individual requirements. We look forward to continuously expanding the system.”

Challenge

One of the challenges was to realize a quick proof of concept, which, if the test is successful, can be expanded into a finished, future-proof solution.

At the same time, the production machines had to be made Internet-enabled to enable continuous monitoring.

Another challenge was to be able to monitor several machines simultaneously on several terminals or from mobile devices by different user groups.

Realization

The solution was implemented on the basis of loosely coupled components, including a backend for storing and real-time evaluation of machine data, alarm generation and escalation control, a responsive front-end application for user interaction for multiple user roles, and adapters for receiving individual machine data.

BITS took on all IT roles during implementation, from conception to project management and individual development to operation of the finished solution. Continuous further development is also carried out by BITS.

Das agile Vorgehensmodell der BITS

Die Umsetzung des Projektes erfolge auf Basis des agilen Vorgehensmodells MVP by BITS und ermöglichte einen GoLive 6 Wochen nach der Idee und Zieldefinition.

Project roles at a glance

BITS experts took on the following roles in this project.

Tools & Technologies

The following tools and technologies were used in this project.

CONTACT

Would you like to find out more?

Are you interested in learning more about the possibilities of digitization in your company? Are you facing similar challenges or have you planned specific projects in your company? Please contact us for a detailed consultation.

Send us an e-mail directly to [email protected] – we look forward to working with you to shape the future of your IT landscape!

You can also make an appointment directly in our calendar.